Designing a filling production line is a critical task for manufacturers in various industries, including food and beverage, pharmaceuticals, and cosmetics. A well-designed filling line can enhance efficiency, reduce waste, and ensure product quality. Here are the key steps to consider when designing a filling production line.

1. Define Your Requirements

The first step in designing a filling production line is to define your specific requirements. This includes understanding the type of products you will be filling, the volume of production, and the packaging formats. For instance, will you be filling liquids, powders, or granules? Will the products be in bottles, jars, or pouches? Knowing these details will help you choose the right equipment and layout for your production line.

2. Choose the Right Equipment

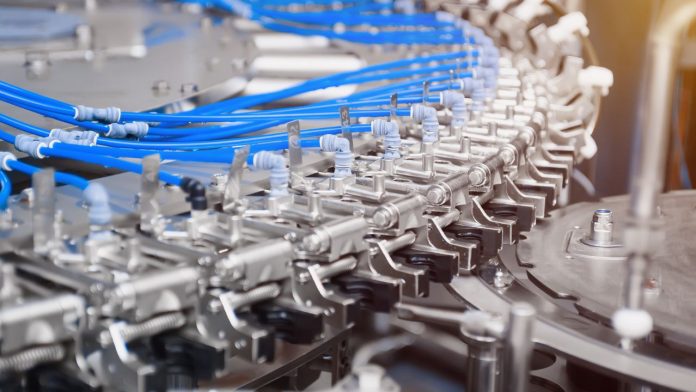

Once you have defined your requirements, the next step is to select the appropriate filling equipment. There are various types of filling machines available, including gravity fillers, pressure fillers, vacuum fillers, and piston fillers. Each type has its advantages and is suitable for different products. For example, gravity fillers are ideal for thin liquids, while piston fillers work well for thicker products. Additionally, consider other equipment needed for the production line, such as conveyors, capping machines, and labeling machines.

3. Plan the Layout

The layout of your filling production line is crucial for optimizing workflow and efficiency. A well-planned layout minimizes the distance between different stages of the production process, reducing the time and effort required for product handling. Consider the following when planning your layout:

Flow of Materials: Ensure a logical flow of materials from receiving to filling, capping, and packaging. This helps prevent bottlenecks and improves overall efficiency.

Space Utilization: Make the best use of available space. Consider vertical space for storage and equipment to maximize the production area.

Accessibility: Ensure that all equipment is easily accessible for maintenance and cleaning. This is essential for minimizing downtime and ensuring product quality.

4. Implement Automation

Automation can significantly enhance the efficiency of your filling production line. Automated filling machines can increase speed and accuracy while reducing labor costs. Consider integrating sensors, control systems, and software to monitor and control the filling process. Automation can also help with data collection, allowing you to analyze production performance and make informed decisions for improvements.

5. Ensure Quality Control

Quality control is a vital aspect of any filling production line. Implementing quality control measures at various stages of the production process helps ensure that the final product meets the required standards. This can include:

Regular Equipment Calibration: Ensure that filling machines are regularly calibrated to maintain accuracy.

In-Process Testing: Conduct tests during the filling process to check for consistency in fill levels and product quality.

Final Inspection: Implement a final inspection stage to check for packaging integrity, labeling accuracy, and overall product quality.

6. Train Your Staff

A well-trained workforce is essential for the success of your filling production line. Provide training for your staff on operating the equipment, understanding the production process, and adhering to safety protocols. Regular training sessions can help keep your team updated on new technologies and best practices, ensuring smooth operations.

7. Monitor and Optimize

After the filling production line is up and running, it is important to continuously monitor its performance. Use key performance indicators (KPIs) to assess efficiency, production speed, and product quality. Regularly review this data to identify areas for improvement. Optimization may involve adjusting equipment settings, changing workflows, or upgrading machinery to enhance performance.

Conclusion

Designing a filling production line requires careful planning and consideration of various factors, including equipment selection, layout, automation, and quality control. By following these steps, manufacturers can create an efficient and effective filling line that meets their production needs. Continuous monitoring and optimization will ensure that the production line remains competitive and capable of adapting to changing market demands. For more information on filling solutions, visit confilling.com.